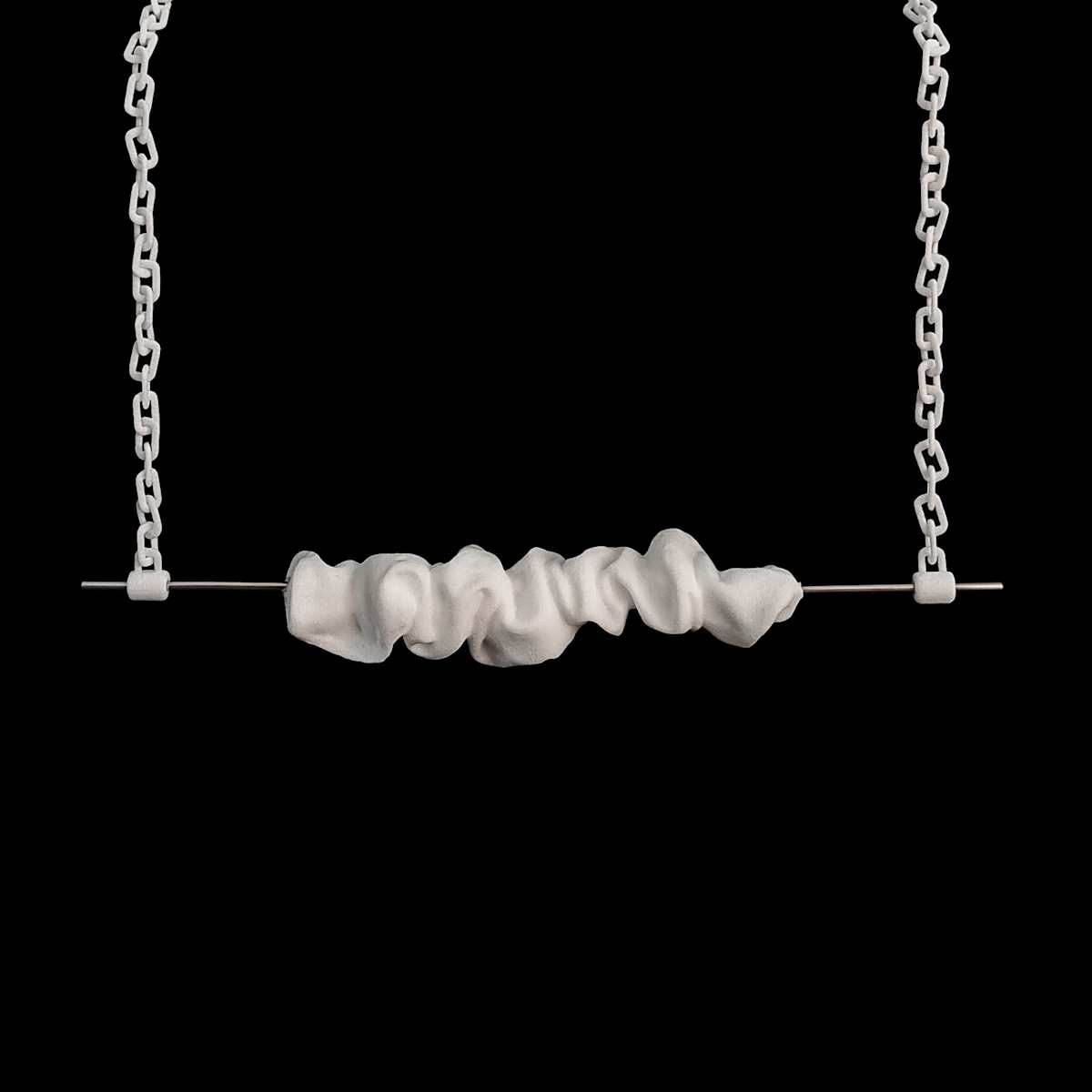

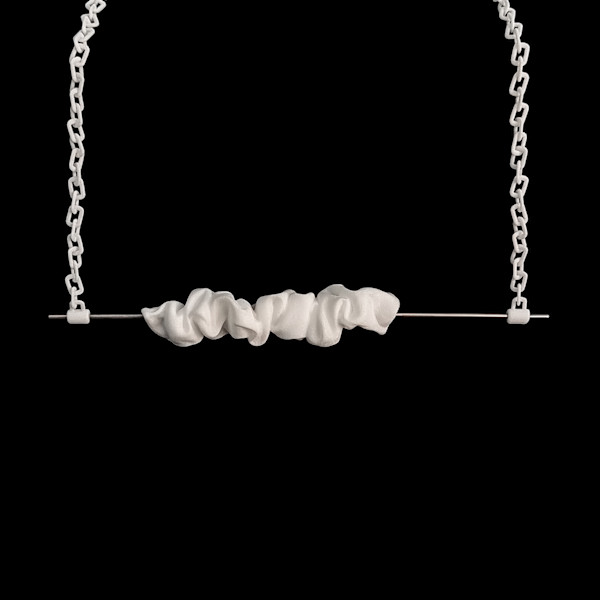

One strategy for the creation of authentic contemporary jewellery objects is to only use those aspects that work best for a specific material, process or technique and to combine them in a hybrid practice. The Scrunchie skewers were not designed in CAD. Instead, they were made by cutting store-bought scrunchie hair ties and skewering them onto a metal rod. The assembly was then 3D-scanned with the Polycam app on my Android smartphone. I used the geometry output as is. Ironically, the chains attached to these skewer pendants were custom-designed for these necklaces. This is different from fine jewellery practice, where chains are typically purchased commercially. In this case, the pendants were commercially sourced, while the chains were uniquely created, reversing the usual relationship between mass-produced and tailored components.

One major advantage of working this way was the ease with which I could capture the aesthetic of scrunched-up fabric. There was no need to labour over whether the model looked realistic, as the model was an exact reproduction of an actual scrunchie. Once the model file was created, I could leverage the benefits offered by CAD and 3D printing: I was able to scale the design as needed, incorporate a hole for the metal skewer that attaches it to the 3D-printed chain, and send it to be 3D printed. In future, the digital file will allow for effortless reproduction in any size, whenever needed.

- Subject Matter: Necklace

- Current Location: Artist's studio

- Collections: Hesti Wade Master of Art and Design: Jewellery Design & Manufacture